AIMS Ltd has developed significant expertise in the fabrication

and pre-treatment of powder metal containments destined to be

consolidated through the application of Hot Isostatic Pressing.

Considerable skill with the welding of sheet metal shapes is required,

but equally close control of both the filling of powder into the

shaped enclosure, and the removal of air and adsorbed gases

from the powder volume is vital to achieve optimum properties.

By way of example the development of large and dense

powder blocks for the manufacture of Sputtering Targets

produced for a recent client, confirmed a level of quality

improvement using the AIMS route much superior to similar

parts produced by other suppliers.

AIMS Ltd has developed significant expertise in the fabrication

and pre-treatment of powder metal containments destined to be

consolidated through the application of Hot Isostatic Pressing.

Considerable skill with the welding of sheet metal shapes is required,

but equally close control of both the filling of powder into the

shaped enclosure, and the removal of air and adsorbed gases

from the powder volume is vital to achieve optimum properties.

By way of example the development of large and dense

powder blocks for the manufacture of Sputtering Targets

produced for a recent client, confirmed a level of quality

improvement using the AIMS route much superior to similar

parts produced by other suppliers.

Commenting on this difference, Rod Tompsett, Group Chief Executive said, "this feedback was not entirely unexpected". Many providers of encapsulation services for powders apply somewhat more limited and less customised evacuation procedures to PM shapes, which leads to a greater degree of impurity, particularly Oxygen within the final product.

In recent work with the Royce Advanced Metal Processing Group at Sheffield University we demonstrated that with the consolidation of pure Chromium powders, with Oxygen levels of typically 250 ppm, this Oxygen level can be increased by a factor of 2.5 to 3 times within the final dense part using standard degassing practices. By contrast the application of the AIMS practice reduces this change significantly by more than 60 %, and such a positive change will be still more significant for larger and more complex parts.

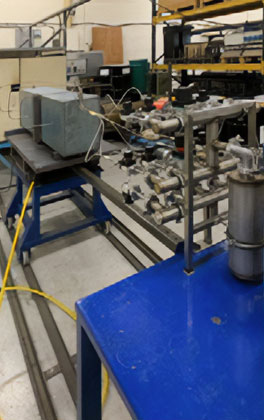

Taking advantage of this knowledge, AIMS has recently invested substantially to increase its overall encapsulation

capacity and the size of powder parts that can be made ready for Hip treatment.

October 2024

The production of near net shape metal parts using metal powders and consolidated

by Hot Isostatic Pressing (Hip) has been under development for many years,

and with both experience and computer modelling, the final dense shape can be

predicted within a few millimetres of its final required size. For many applications

such a tolerance is more than adequate to meet final machining needs and is

competitive with other forming processes particularly for larger parts.

The production of near net shape metal parts using metal powders and consolidated

by Hot Isostatic Pressing (Hip) has been under development for many years,

and with both experience and computer modelling, the final dense shape can be

predicted within a few millimetres of its final required size. For many applications

such a tolerance is more than adequate to meet final machining needs and is

competitive with other forming processes particularly for larger parts.

Where however, the final product requires to deliver wear and corrosion resistive surfaces within both large diameter and long tubular bores, such oversize powder shapes are both difficult to maintain product straightness and surface layer thickness, and are costly to machine to meet final product tolerances.

The requirement to provide consistent straightness and "as-Hip" processed dimensions of only a fraction of a millimetre machining tolerance within the bore, has previously been attempted using solid metal formers which are subsequently removed by machining. Selecting the correct material for such a former is problematic. Diffusion from the former into the powder can modify final surface properties, and with uneven packing density of the powder, the former can distort during Hip processing leading to an inconsistency of product straightness.

Reflecting on this technological need for the manufacture of extrusion modules for plastic and food processing, AIMS Ltd. has developed and patented an innovative processing technique using an easily removable ceramic former which eliminates any alloy diffusion issues and maintains product straightness regardless of powder packing density, or the length or diameter of the bore required.

The process is believed to be appropriate for other hollow parts, or for those having a complex arrangement of intersecting bores. Additionally, the former technology may be appropriate for the re-sizing of worn tubular parts.

AIMS Ltd. has identified that this ceramic former process technique can both shorten delivery times ,reduce both manufacturing and finishing costs, and broaden the range of sizes of extrusion module parts that can be improved with advanced surface coatings.

October 2024

AIMS Ltd, through its specialisation in advanced Powder Metallurgy processing, has pioneered the development of improved performance of wear parts for the food and plastic extrusion market. The Sagittite process pioneered and patented by AIMS, has increased operating lifetimes of extrusion equipment by an order of magnitude over established methods of production by harnessing the flexibility of Hot Isostatic Pressing (HIP) technology. Having achieved such impressive results from the application of HIP technology, our most recent activity supported by independent UK based development organisations, has been to better understand the potential for supply chain optimisation. From powder supply, to processing conditions, the spectrum of opportunity to improve both understanding and characterisation of the Sagittite Optima product range has been improved over the last 12 months. During this period of Supply Chain optimisation , both new and existing IPR has also been considered to further enhance the differentiation of AIMS processing technology. Our new programme designed to Disrupt traditional manufacturing would be to secure a reduction in manufacturing time of 50%, and a cost of manufacture saving of 40%. With a unique, UK based supply chain for ready to fit parts, we see this as a major step forward to service the global extruder market. Part of this Disruptive technology has previously been demonstrated within a different sector, and AIMS believes that opportunity now exists to transfer and scale this processing technique into the international extrusion market.

In combination with the manufacturing change envisaged by the Disruptor Project, AIMS has also recognised that it would be possible to apply the same processing technique for the rapid recovery of worn and redundant high value extrusion parts. "Sagittite Green" would provide a unique service in both the supply of new and reclaimed parts, with the potential of introducing a completely new business model to the extruder market. Manufacturing of a new part, and with subsequent re manufacturing, would offer enhanced sustainability for high value parts,and a product leasing option from a pool of readily available refurbished extruders rather than the more cost intensive outright capital purchase.As a small business, AIMS has specific resources of value to this new venture, but seeks to engage with other like minded, development and innovation led organisations who may wish to contribute appropriate resources within the phases of the project and equally, share in the potential upside benefits from this new and innovative technology. This introduction therefore sets out the broad principles for such a project and seeks interest and further discussion under appropriate NDA cover.

As polymer compounds adapt to provide additional functionality, particularly for packaging, operating conditions in raw material manufacturing plant is accelerating the need for improved wear resistance, particularly in equipment used for pellet manufacture.

Sagittite alloy grades developed by AIMS are being recognised as providing improved erosion and corrosion capability and re-equipping plant with Sagittite 10, a nickel based alloy, has lifted operational performance by a factor of 5. Users are confirming that processing downtime has been significantly improved and the consistency of pellet production within processing campaigns has seen a similar advantage. Standard parts have been re-engineered in the new powder alloys, but in the next stage of improvement the Sagittite grades will be applied selectively to create a composite part.

With the steady increase in demand for longer processing campaigns

for equipment operating in the food, snacks and pet foods

sectors, the demand for improved properties of critical components,

ie extrusion barrels, has required systematic improvement to

materials in direct contact with the product ingredients. AIMS,

specialising in the use of Sagittite powder alloys has embarked

upon a detailed analysis of the powder grades it uses for extrusion

liners and through this work has established a further refinement

of the structure and properties of its products. Since the failure

of extrusion parts is often linked to wear and corrosion fatigue,

the refinement of powder size and cleanliness has been of specific

interest.

This, combined with the already established practice for Hip

processing, is leading to lifetime improvements over conventional

materials by up to a factor of 10. With improved powder preparation

and attention to process improvement, this is marking AIMS as the

supplier of choice.

Interestingly, this same programme of work is leading to cost

savings which are being passed onto clients, so that lifetimes can

increase but at lower prices than previously achieved.

As the demands on extruder equipment increase, be this for Food or

Polymer processing, the investment in new, high value materials has

become important to maximise machine efficiency.

Inevitably after multiple campaigns extruder surfaces are worn

beyond operational tolerance, and this regularly leads to the

removal and scrapping of extruder segments and the introduction of

new parts. With significant knowledge of extruder operating

practice, and the application of powder technology and Hipping to

produce extruder parts, AIMS has commenced early work on the

recovery of worn extruder barrels with the objective of

refurbishing these parts,and returning these parts to active

use. AIMS is seeking to link with extruder users who wish to take a

more active and collaborative role in this work. Interested

users should contact AIMS through bernierickinson@icloud.com